Heat exchangers are essential components of many industrial processes because they may lower energy costs, increase system performance, and improve energy efficiency. They can, for instance, warm entering fluids, recover waste heat from exhaust gases, and keep diverse processes operating at the proper temperature. Additionally, they are a part of common equipment like water heaters, air conditioners, and refrigerators.

Metal, silicone, cork, rubber, and other materials are used to make Gaskets for Heat Exchanger is crucial parts that keep the junction between the two portions of the heat exchanger sealed. A mechanical seal called a gasket is placed between two surfaces to stop leaks into or out of the linked items when they are compressed.

They stop fluid and gas leaks from the heat exchanger, which can cause safety risks, environmental pollution, and decreased performance. Usually, they are put in a groove that runs between the heat exchanger’s two parts. The bolts holding the two parts together compress the gasket, forming a seal. To guarantee a leak-proof seal, it’s critical to select the appropriate gasket material and size for the application and to install it properly.

What is the Heat Exchanger Gasket Specialty?

- Securing

Heat exchanger gaskets’ main job is to keep fluids from leaking by sealing the tubes, headers, and end plates, among other components. By doing this, it is ensured that the hot and cold fluids stay apart, avoiding contamination and preserving heat transfer efficiency.

- Resistance to Temperature

Since heat exchangers work in environments where both extremely hot and cold fluids may be present, the gaskets they utilize are made to tolerate a broad range of temperatures. They must not deteriorate or distort in order to retain their sealing qualities.

- Chemical Impediment

Gaskets for Heat Exchanger are frequently in contact with different liquids and chemicals, particularly in industrial and chemical processing settings. Materials that are resistant to corrosion and chemical damage are used to make specialty gaskets.

- Resistance to Pressure

There can be large pressure differentials while heat exchangers are operating. For gaskets to keep a tight seal, they must be able to endure certain pressures.

- Respect for Regulations

Heat exchangers are subject to safety and environmental laws in various businesses. To satisfy these requirements and guarantee the heat exchanger’s safe functioning, special gaskets could be needed.

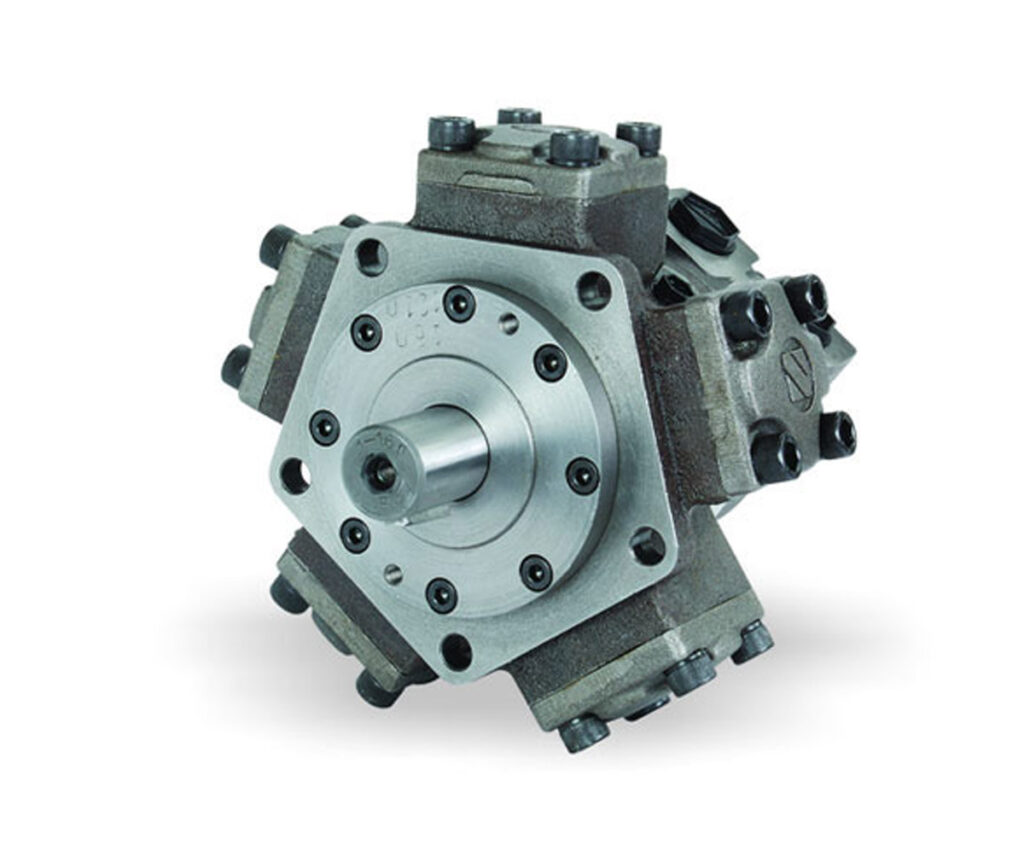

Locate the Ideal Marketplace with Used Electric Motors for Sale

Electric motors that have been utilized in a range of applications in the past are known as used motors. They may have been utilized in appliances, industrial machines, or other gadgets. Because they are frequently available for a much lower price than new motors, used electric motors can provide good value for the money. Electric motors that have been owned and used before being put up for sale as used or pre-owned machinery are referred to as used electric motors.

Thus, if you’re searching for Used Electric Motors for Sale, pick Amaf Marine or another trustworthy service provider. These motors aren’t brand-new; they’ve been taken out of their original machinery or applications and may have had some use. Commonly found in a variety of states and from a number of sources, such as surplus sales, industrial equipment auctions, and specialist used equipment sellers, are used electric motors.

Saving money is the main justification for thinking about secondhand electric motors. They are a desirable alternative for people and companies wishing to save back on equipment acquisition expenses because they are usually less expensive than brand-new motors.

Why Amaf Marine?

When AMAF Marine was founded, its mission was to provide machines and replacement parts worldwide without fail, meeting client demands. Our primary focus is on providing replacement parts for heavy machinery in large industrial facilities and oil refineries, including marine engine spares.

Over the course of more than 20 years, we have broadened our areas of interest to include dealing in all types of machinery and equipment to meet the demands of the industry. Over the years, the company has expanded from a modest commercial establishment to a global customer.

Today, AMAF Marine is an international firm that is family-owned and run, providing a wide range of machinery spares to various sectors in the world. Our only Aim is to deliver a perfect machinery part with minimum required time, so you can achieve a high efficiency in your machinery.