The push for sustainability in semiconductor manufacturing has become more urgent as 3D technologies grow increasingly prevalent. These advanced chips, designed for higher performance and miniaturization, also pose challenges in terms of waste generation and energy demands. Through AI-driven process optimization, advanced lithography and material recycling initiatives, manufacturers are paving the way for environmentally sustainable 3D semiconductor production. Erik Hosler, a specialist in eco-conscious semiconductor innovation, highlights the critical role of these advancements in reducing environmental impact without compromising technological progress.

AI-Driven Process Optimization: Smarter, Cleaner Production

Artificial intelligence (AI) is transforming the way semiconductors are manufactured by streamlining processes to reduce waste and energy consumption. Machine learning algorithms analyze vast amounts of production data in real-time, identifying inefficiencies and suggesting adjustments to improve resource usage.

For instance, AI can dynamically optimize material deposition rates and align etching processes to minimize errors, ensuring fewer defective chips and reduced resource waste. Additionally, predictive analytics allow fabs to preemptively address equipment maintenance issues, preventing costly downtime and energy overuse.

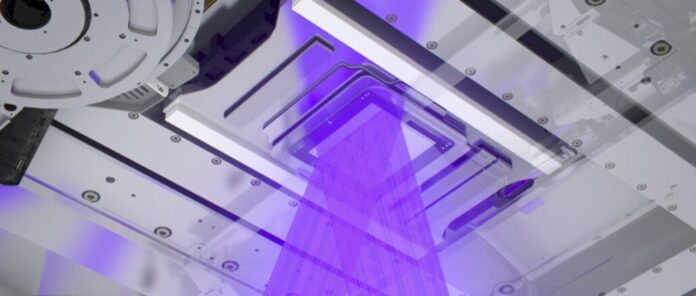

Advanced Lithography: Precision Meets Sustainability

Lithography is a cornerstone of semiconductor production, but traditional methods often consume significant amounts of energy and materials. Modern advances in extreme ultraviolet (EUV) lithographyare addressing this challenge by improving precision and reducing the number of production steps required.

EUV technology enables higher resolution at the nanoscale, which minimizes material waste while increasing yield rates. This efficiency not only conserves resources but also reduces the carbon footprint associated with producing 3D-stacked chips.

Erik Hosler mentions, “Light source development and lithography advancements are shaping the future of semiconductor applications, where light will drive the next wave of innovation.” These cutting-edge techniques exemplify how sustainability and technological advancement can coexist.

Material Recycling Initiatives: Closing the Loop

In addition to process optimization and advanced tools, material recycling is becoming a key pillar of sustainable semiconductor manufacturing. Precious metals, such as gold and copper, are recovered from production scrap and defective wafers, while silicon recycling reduces the need for virgin materials.

By implementing closed-loop systems, manufacturers significantly lower material waste and energy consumption while reducing dependency on resource-intensive mining practices. These recycling initiatives not only promote environmental stewardship but also provide cost savings for fabs.

Pioneering a Greener Future

Sustainable practices in 3D semiconductor manufacturing are proving that high performance doesn’t have to come at the expense of the environment. By leveraging AI-driven optimization, advanced lithography and recycling, the industry is reducing its environmental footprint while maintaining cutting-edge innovation.

As these initiatives continue to evolve, they set a precedent for other industries, demonstrating that sustainability and progress can go hand in hand in the pursuit of a greener future.