The metalworking sector continues to transform through automation, and at the centre of it lies CNC machining. From small-batch prototypes to full-scale production, CNC technology is redefining efficiency, accuracy, and reliability for manufacturers across Canada. With unmatched speed and precision, CNC systems are becoming critical to custom metal fabrication in Toronto’s competitive industrial environment.

Businesses needing precision-driven solutions increasingly rely on advanced CNC processes to streamline their workflows.

Precision at a Whole New Level

CNC machining operates with tolerances down to microns. This level of accuracy supports the production of highly detailed components that must perform under stress or in regulated applications. Consistency across multiple runs allows businesses to scale without compromising part integrity.

With CAD/CAM software integrations, changes in design can be implemented and tested with minimal disruption. The result is a smoother transition from concept to finished part.

Faster Turnarounds with Automated Production

Automation is one of the biggest value drivers in CNC metalwork. These machines run with limited supervision and can operate around the clock. That means fewer bottlenecks and faster delivery, even for complex or high-volume jobs.

Businesses benefit from:

- Reduced manual labour

- Shorter lead times

- Greater scheduling flexibility

CNC has become a vital part of metal fabrication in Toronto, especially in industries where time-to-market affects profitability.

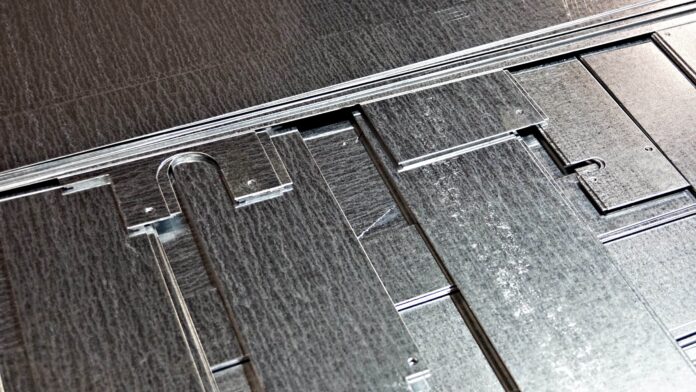

Improved Design Flexibility for Complex Projects

Advanced CNC tools support multi-axis machining, which makes it easier to produce:

- Geometrically complex parts

- Angled surfaces and undercuts

- Precision cavities and slots

This flexibility benefits industries such as HVAC, lighting, transportation, and equipment manufacturing, all requiring reliable, intricately shaped components.

Reduced Waste and Better Material Efficiency

Material efficiency directly affects cost. CNC machines reduce waste by precisely cutting only what’s needed. Nesting algorithms and toolpath optimization maximize yield from each sheet or billet.

In stainless steel fabrication, where material costs are higher, efficient use of stock material significantly impacts project margins.

Local Industries Driving Demand for CNC Fabrication

Toronto’s industrial growth is fuelling CNC investment across sectors. Companies need durable, custom-fit parts delivered fast, and CNC allows suppliers to meet that demand without delays or quality gaps.

CNC fabrication supports small local shops and large OEMs by offering scalable, repeatable, and highly customizable manufacturing.

The Role of Skilled Operators and CAD Designers

Even with automation, skilled professionals remain essential. Operators program the machines, manage calibration, and troubleshoot issues. CAD designers ensure that files translate correctly into physical components.

This human-machine collaboration continues to define the success of custom metal fabrication across Ontario.

As software advances and machine precision improves, CNC will become even more accessible to small and mid-size manufacturers. Integration with AI, real-time monitoring, and predictive maintenance will optimize workflows.

Contact Weldflow Metal Products to explore how our CNC capabilities support your fabrication goals with precision, speed, and material integrity.