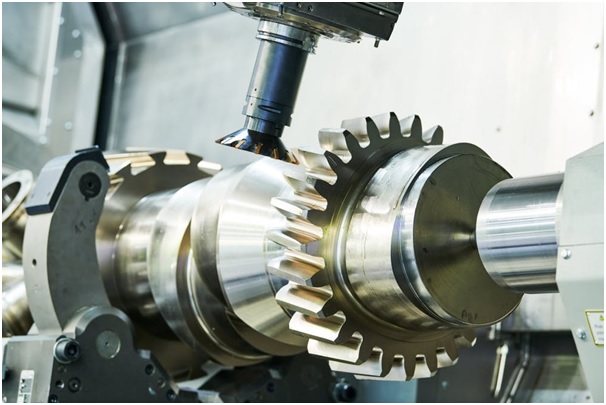

A significant machine part that plays a role in various machinery is the gear. Keeping its cruciality in mind, adopting the right way of manufacturing is a must. That being said, there are different methods by which the gear and its teeth can be cut using the best tools. It involves gear shaping and gear shaving cutters of various models to incorporate into gear manufacturing units. Its usage should be known to every industrialist, and with this knowledge comes the right implementation of techniques for the most rewarding manufacturing outcomes. Give a shot to the details for improved results in your production unit.

How does gear shaving help?

The critical industries that require good performance in whatever they do and invent for the world expect high-quality gears to operate the machinery and applications better. It rises the need for the technique, gear shaving, which is a process applied at the finishing stage of gear production.

The goal is to enhance the surface finish so that when it operates, the noise output profile is low, providing a smooth functioning of appliances in crucial industries such as automobile, industrial manufacturing units and aerospace industry.

The equipment used in these areas will have high performance, and so its functioning should be consistent in smooth delivery and quality. With gear shaving cutters put into action, the gear’s teeth will be profiled properly, making it the best product to be installed in applications. It is vital to know how shaving is done to hire gear shaving cutter suppliers to ease gear production and its outcomes.

Process of gear shaving

As said, the gear shaving process removes excess material from the tooth profile of the gear. Firstly, the gear is placed on a machine, which is called the shaving head. It contains a shaving cutter on the head. Once the gear is placed, the shaving cutter is rotated at a controlled speed, allowing it to cut the excess material properly, resulting in an accurate finish.

The material removed totally depends on the pressure and speed at which the shaving cutters operate. Modern applications rely on high-quality and precisely cut gears, and using gear shaving cutters, producing them happens seamlessly at the gear manufacturing industries.

Also, gear shaving cutters types include plunge, transverse, underpass and diagonal shaving cutters. Understanding this process is critical for those working as engineers in designing good gear systems or an industry owner looking to improve the production quality of gears.

Gear shaving – a gift to gear production!

The best reasonable way to bring down the gear manufacturing costs and reduce gear-cutting errors is through the deployment of gear-shaving cutters. All one has to try is hire a reliable and well-experienced shaving cutter supplier to fulfil production demands. Most gear manufacturing units thrive in the market by identifying the most rewarding techniques to improve the results effectively.

Gear shaving can be one of them when understanding its role in the best quality production. Talk to a supplier and hire them now to meet your needs appropriately.