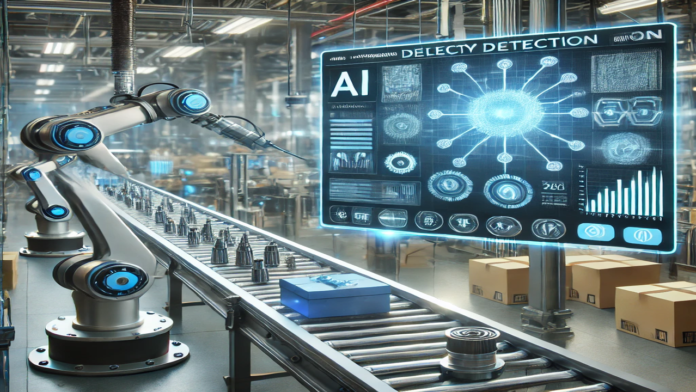

Quality control is the backbone of any successful business. Even a minor defect can lead to customer complaints, financial losses, and a damaged reputation. Traditionally, businesses relied on human inspection, but manual checks are slow, inconsistent, and prone to errors. Now, AI-powered devices are transforming the way businesses ensure quality.

From smart cameras that detect the tiniest flaws to AI-driven sensors that monitor every production detail, these advanced tools make quality control faster, more accurate, and highly efficient. They not only identify defects but also predict problems before they happen, helping businesses save time and money.

Let’s explore how AI devices are revolutionizing quality control and making businesses more competitive than ever.

Source: Go online

AI Cameras Spot the Smallest Flaws

AI-powered cameras are a game-changer in quality control. These smart cameras use advanced image recognition and AI-driven PC technology to scan products in real time and detect the smallest defects. AI cams find small marks, color shifts, or gaps at once.

- Fast Scan: They check lots of goods in no time.

- Sharp Eye: They spot tiny flaws with smart tech.

- No Rest Needed: They do not get tired, so checks stay right.

- Gets Smarter: They learn and get sharp with time.

Many fields use AI cams to cut waste and send out top goods.

AI Systems Eliminate Human Errors

One big hard part of hand checks is man slip-ups. Work hands can miss flaws due to tired minds, loss of focus, or shifts in view. AI stops this by checking on its own.

AI tools look at shapes and find flaws that man eyes may not see. They scan lots of facts fast to make sure each piece is top-notch.

In cloth work, AI scans for rips or bad stitch work. This helps make sure each load is up to the mark. This cuts bad goods and makes folks more glad.

Smart Sensors Check Every Part

Smart sensors are responsible for quality control by making sure each component of a product is up to standard. These sensor devices, equipped with artificial intelligence, take precise measurements of dimensions, weight, texture, and even the chemical makeup of materials.

They identify anomalies in raw materials prior to production so that only quality inputs are utilized. In food production industries, sensors track temperature, humidity, and moisture levels to ensure freshness and avoid spoilage.

Equivalently, in manufacturing, they inspect coatings, finishes, and alignment to have perfect assembly. Through offering real-time information, smart sensors assist companies to have consistency, lower defects, and enhance overall product reliability.

AI Robots Speed Up Sorting

Sorting by hand takes a lot of time and does not work well. AI bots make it fast and spot-on.

These bots:

- Find flaws at once: AI bots scan each piece.

- Toss bad ones out: If it is not right, the bot moves it.

- Group by key traits: AI bots sort by hue, size, weight, and form.

- Work non-stop: Bots do not rest, so work moves fast.

Firms that ship, build, and make goods gain much from AI sort tools. They save time and cut costs.

AI Predicts Problems Before They Happen

AI finds flaws fast and stops them, too. Smart tools scan old facts to spot trends that may cause harm. AI checks each step and sees small shifts that hint at a flaw. This helps firms fix things quickly, cut waste, and save cash.

How AI helps stop flaws:

- Finds trends in work steps to spot flaws.

- Warns staff of risks in time.

- Gives ways to fix flaws quickly.

- Cuts waste by stopping bad goods.

- Speeds up work by keeping things smooth.

Automated Reports Help in Decision-Making

AI checks goods and makes quick notes to help firms make smart picks. These notes show:

- Flaws in goods: Helps firms fix bad parts.

- How tools work: Makes sure all parts run well.

- Work speed: Helps cut slow spots.

- Ways to save cash: Cuts waste and saves stock.

In drug making, AI notes track dirt risks and help keep work clean so safe pills reach all.

AI Enhances Safety in Factories

AI not only improves product quality but also enhances workplace safety. AI-powered monitoring systems:

Preventing Workplace Accidents

AI enhances not only the quality of products but also the safety of the workplace. AI-based monitoring systems are able to identify dangerous situations like overheated machinery, gas leaks, and equipment failure prior to severe accidents. The systems provide workers and supervisors with immediate alerts, enabling prompt action to avoid injuries. AI-based robots can also perform risky tasks, minimizing human workers’ exposure to hazardous environments.

Ensuring Compliance with Safety Regulations

AI makes sure that factories adhere strictly to safety standards by monitoring working conditions in real-time. AI sensors and cameras monitor if workers are wearing protective equipment, adhering to procedures, and staying at a safe distance from dangerous areas. Such systems prevent companies from facing legal complications, minimize workplace accidents, and provide a safer working environment for every employee.

Final Thoughts

AI is transforming quality control in all industries. Companies are observing tremendous gains in efficiency, accuracy, and cost reductions, from intelligent cameras and sensors to predictive analytics and AI robots. With AI, businesses can guarantee that only the finest products make it to consumers, resulting in improved brand equity and increased profits.

Investing in AI quality control is not only a trend—it’s the future. Companies that adopt AI today will be ahead of the curve in producing perfect products tomorrow.